Key Takeaways:

- Coil springs provide high torque capacity and are ideal for heavy-load handling.

- Coil springs offer customization options and can be made from different materials.

- Coil springs are easy to install and replace, minimizing downtime.

- Wave springs are compact and suitable for applications with space constraints.

- Wave springs distribute loads evenly, reducing stress concentration and improving durability.

- The choice between coil and wave springs depends on power and torque requirements.

- Coil springs offer more design flexibility, while wave springs optimize space utilization.

- Coil springs have a long history of reliable performance and can withstand harsh conditions.

- Wave springs provide efficient performance in compact clutches.

- Consider the clutch application, consult with experts, and weigh the costs and budget when choosing a spring.

In this guide, you will know the answer to the question, “Is a coil or wave spring right for your power grip clutch?”

Understanding the Different Types of Power Grip Clutch Springs

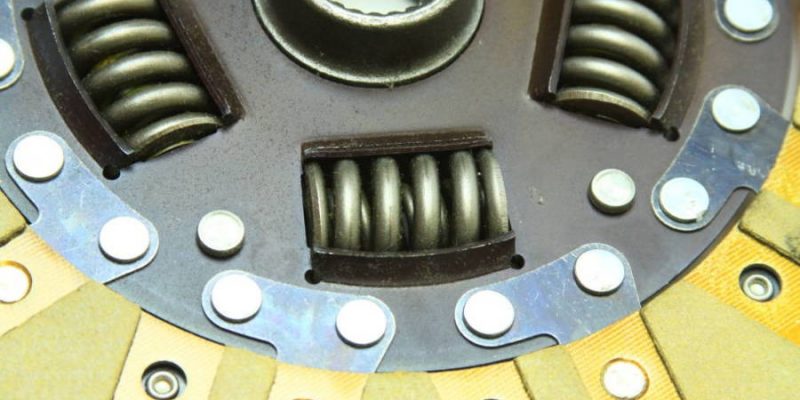

Regarding power grip clutches, the choice of spring plays a significant role in determining the clutch’s performance and efficiency. Two popular options for power grip clutch springs are coil springs and wave springs. Understanding the advantages and benefits of each type will help you make an informed decision when choosing the right spring for your power grip clutch.

The Advantages of Coil Springs

Coil springs have been a staple in power grip clutches for many years and offer several advantages. One of the key benefits of coil springs is their ability to provide high torque capacity. These springs are designed to handle heavy loads and transmit power efficiently, making them ideal for applications that require reliable and robust performance.

Another advantage of coil springs is their wide range of customization options. They can be tailored to specific power and torque requirements, allowing for flexibility in clutch design. Coil springs can be made from various materials, including alloy steel and stainless steel, further enhancing their customization capabilities.

In terms of installation, coil springs are relatively straightforward. They can be easily mounted and replaced, minimizing downtime during maintenance or repairs. This simplicity makes coil springs popular in industries where downtime can be costly.

The Benefits of Wave Springs

Wave springs are a relatively newer power grip technology that offers unique benefits. One of the primary advantages of wave springs is their compact design. These springs are typically thinner and require less axial space than coil springs, making them suitable for space-constrained applications.

Wave springs can still handle high power and torque requirements despite their compact size. They are designed to perform similarly to coil springs while occupying less space. This allows for more design flexibility, especially in applications where every millimeter counts.

Wave springs are also known for their ability to distribute loads evenly. The wave-like structure of these springs ensures that forces are spread out uniformly, reducing stress concentration. This even distribution of loads increases the fatigue life of the clutch, leading to enhanced durability.

Key Considerations for Choosing the Right Spring

Several key factors need to be considered when deciding between coil springs and wave springs for your power grip clutch. These factors will help you determine which spring type is best suited for your specific application.

Power and Torque Requirements

One of the first considerations when choosing a spring for a power grip clutch is your application’s power and torque requirements. Coil springs are preferred if you require high torque capacity and heavy load handling capability. They offer reliable performance and can transmit power efficiently.

On the other hand, if your application has strict space limits but still requires significant power and torque, wave springs provide a compact solution without compromising performance.

Space Constraints and Design Flexibility

The amount of space available for the power grip clutch assembly is an important factor to consider. Wave springs are a great option if your application has limited axial space, such as automotive clutches or small machinery. Their thin profile allows for more compact clutch designs without sacrificing performance.

For applications with ample space, coil springs offer more design flexibility. These springs can be customized to fit specific space requirements, and their installation and replacement are straightforward.

Fatigue Life and Durability

The spring’s fatigue life and durability contribute to the power grip clutch’s overall longevity and reliability. Coil springs are known for their toughness and ability to withstand heavy loads over extended periods. Their robust construction and material options make them highly durable.

Wave springs, although compact, also offer an excellent fatigue life. The even distribution of loads in wave springs reduces stress concentration, increasing clutch durability. It’s important to consider the expected lifespan of your power grip clutch and choose a spring that can withstand your application’s demands.

Comparing Performance and Efficiency

Both coil springs and wave springs offer excellent performance and efficiency in power grip clutches, but there are some differences to consider.

Coil Springs: A Look at Performance Characteristics

Coil springs have a long history of reliable performance in power grip clutches. Their ability to handle high torque capacity and heavy loads makes them a popular choice in various industries. Additionally, the customization options with coil springs allow tailored performance to meet specific application requirements.

Coil springs provide consistent friction engagement, ensuring a smooth and reliable power transfer. They can withstand high temperatures and harsh operating conditions, making them suitable for demanding applications.

Wave Springs: Evaluating Efficiency and Effectiveness

Wave springs offer unique efficiency and effectiveness benefits in power grip clutches. Their compact design increases space utilization, making them especially advantageous in applications where every inch matters.

Wave springs distribute loads evenly, reducing stress concentration and enhancing fatigue life. Their ability to provide reliable performance in a smaller package makes them ideal for compact clutches, where space optimization is crucial.

Making the Right Decision for Your Power Grip Clutch

Choosing the right spring for your power grip clutch is a critical decision that requires careful consideration. To ensure you make an informed choice, consider the following:

Understanding Your Clutch Application

Thoroughly assess your clutch application, including power and torque requirements, space limitations, and expected operating conditions. This analysis will help narrow down the options and determine which type of spring best suits your needs.

Consulting with Experts

When in doubt, consult with experts in power grip clutch technology. They can provide valuable insights and recommendations based on their experience and expertise. These professionals can help identify the optimal spring solution for your application, considering performance, space constraints, and durability requirements.

Weighing in on Costs and Budget

Consider the costs associated with each spring option and align them with your budget. While coil springs offer a wider range of customization options, they may also come at a higher price. Wave springs, on the other hand, provide cost-effective solutions for applications with space constraints.

Ultimately, the right spring choice for your power grip clutch will depend on carefully evaluating your application’s unique requirements and performance expectations. Understanding the advantages, benefits, and considerations associated with coil springs and wave springs will enable you to make an informed decision that optimizes the performance and efficiency of your power grip clutch.

Comments